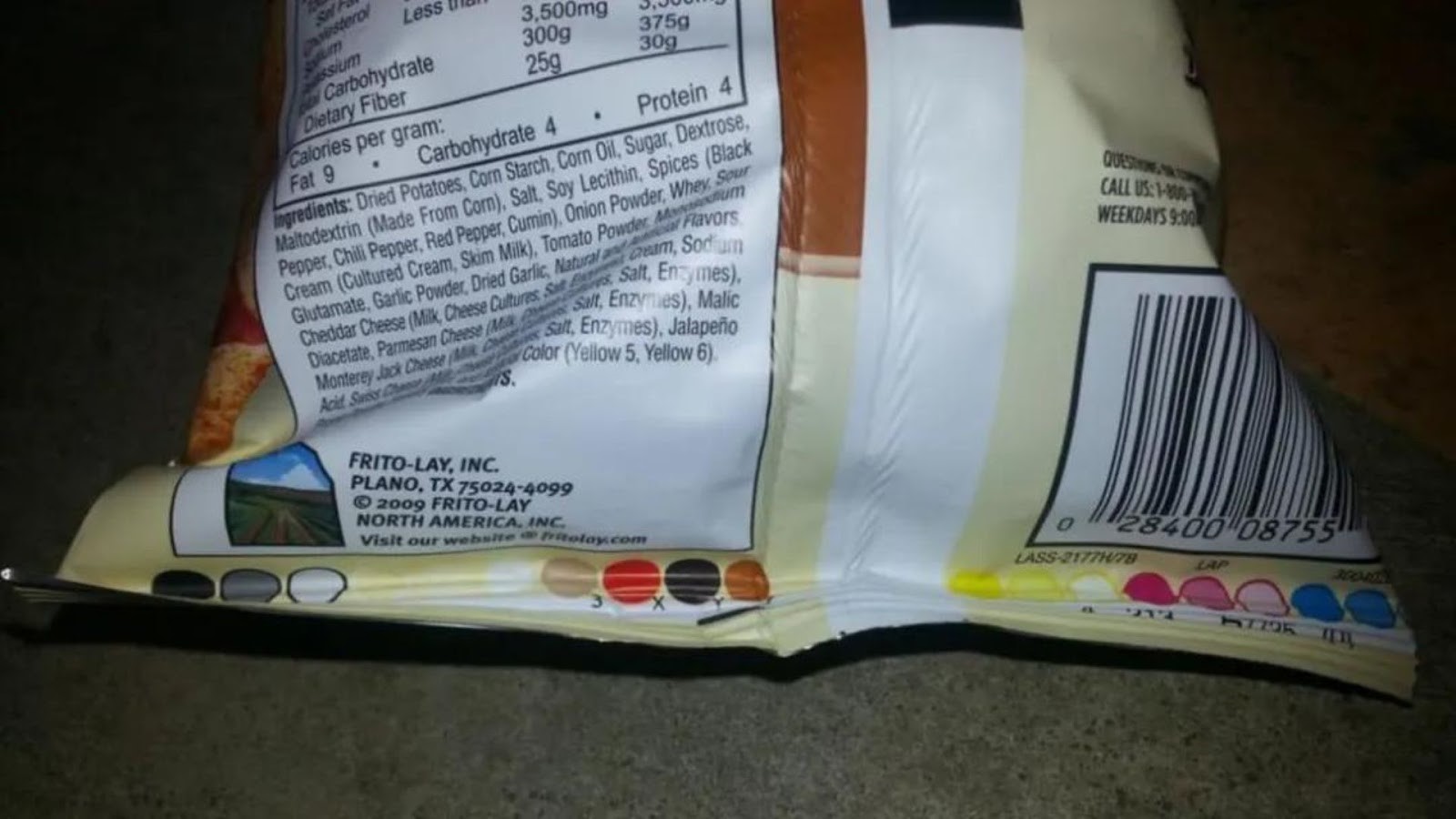

At first glance, food packages offer a plethora of information including brand stories, nutritional facts, ingredients, and serving sizes. However, another less-noticed element is also present on the back of many food packages: a series of colored circles or squares.

Contrary to popular belief, these are not indicators of nutritional content or flavor varieties. They are known as “printer’s color blocks” or “process control patches,” and they serve a unique purpose that has nothing to do with the consumer but is crucial for the production process.

These colored circles come in various shades and can be pink, yellow, blue, black, orange, purple, or green. Their primary function is to assist the printing engineers in maintaining the highest quality of the printed packaging. To provide more insight into this, we consulted an expert printing engineer, Meg Schiraldi.

Schiraldi clarified, “When the packaging is printed, technicians use the colored circles to check that the printing ink is the correct [color] and quality. They compare the color to boxes printed around the world to ensure consistent brand colors.” Most printers commonly use four essential colors: cyan, which is a shade of blue-green, yellow, magenta, and black.

Some printing companies, however, include additional colors such as orange, green, and violet to match specific brand colors that are challenging to create. “That’s why you may see more circles printed on some packages—they need to check each color of ink!” Schiraldi added.

Global Brand Consistency The use of these colored circles is especially important for maintaining brand consistency on a global scale. Whether a consumer is purchasing a product in North America, Europe, or Asia, the packaging should look the same. For example, a yellow packet of M&Ms purchased in Shanghai, Sarajevo, or Sydney would contain peanut M&Ms, and the packaging should reflect the same color quality.

Importance in a Global Market In an increasingly globalized world, consistency in product packaging is critical for brand identity and consumer trust. These circles ensure that the printer’s ink is of the correct color and quality, enabling uniformity in brand colors across the world. The use of printer color blocks is an essential step in quality control, especially for internationally recognized brands that are available in multiple countries.

The colored circles on food packaging, often overlooked by consumers, play a vital role in ensuring the color and quality of the packaging meet set standards. Their primary purpose is to aid the printing engineers in quality control. By helping to maintain consistent brand colors, these circles contribute to brand identity and consumer trust on a global scale.

So, the next time you pick up a food package and notice these colored circles, you’ll know they are a critical part of what keeps your favorite brands consistent, no matter where in the world you are shopping.